Our expertise in laser cutting lies in our vast knowledge of materials and manufacturing processes to produce the highest quality products.

From samples and prototype to large volume production runs. Laser cutting offers our customers quick turnaround, no tooling costs and tolerances to +/- .002”. We have a wide range of non-metallic materials that can be utilized for these projects (reference below). With and without pressure sensitive adhesives, material thickness ranging up to .250”. We also offer a wide range of specialized materials such as EMI and RFI shielding, thermal management, conductive and non-conductive, flame-retardant and UL rated materials.

Our products can be manufactured to accommodate all our clients’ diverse specification and requirements.

- Standard lead times 1-2 weeks

- Certifications – AS9100 / ISO 9001

To learn about our custom gasket and die cutting service, please contact G.F. Cole Corporation today.

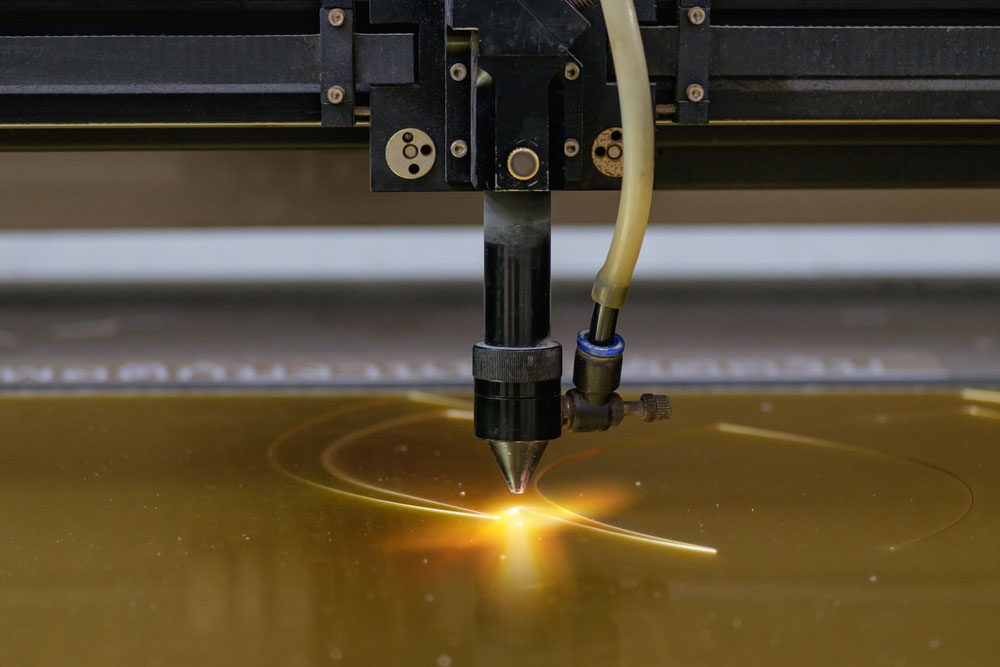

Laser Cutting Equipment

- Our high precision laser cutting equipment can cut very thin, small high tolerance parts, used in electronics, aerospace and various other industries.

Laser Cutting Equipment

- Our high precision laser cutting equipment can cut very thin, small high tolerance parts, used in electronics, aerospace and various other industries.

Laser Cutting Equipment

- The benefits of custom laser cutting include no tooling costs, flexible prototyping, quick sample turn around, as well as shortened lead time for production.

Laser Cutting Equipment

- The benefits of custom laser cutting include no tooling costs, flexible prototyping, quick sample turn around, as well as shortened lead time for production.